Revolutionizing the Future of Transportation: The Manufacturing Process of Electric Car Batteries

Table of Contents

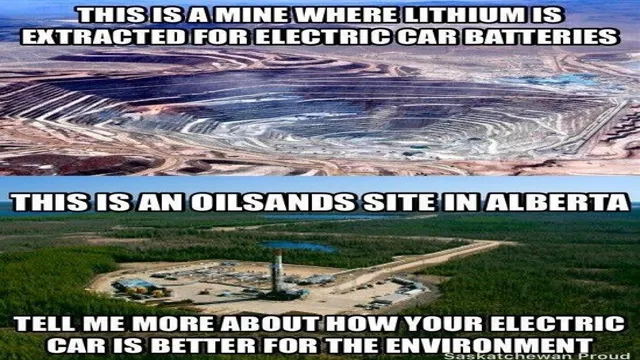

- Shocking Truth: Exploring the Environmental Impact of Electric Car ...

- 1gwh EV Car Battery LFP/Nmc/Lto 30ah 50ah 100ah 200ah Prismatic Cell ...

- Electric Car Battery Life

- Electric vehicle batteries | PPT

- How Is An Electric Car Battery Made? [EV Battery Components]

- An Electric Car Battery That Will Get You From Paris to Brussels and ...

- 1gwh EV Car Battery LFP/Nmc/Lto 30ah 50ah 100ah 200ah Prismatic Cell ...

- One day, your electric car could be one big carbon fibre battery

- Unveiling the Truth: Do Electric Car Batteries Require Fossil Fuels for ...

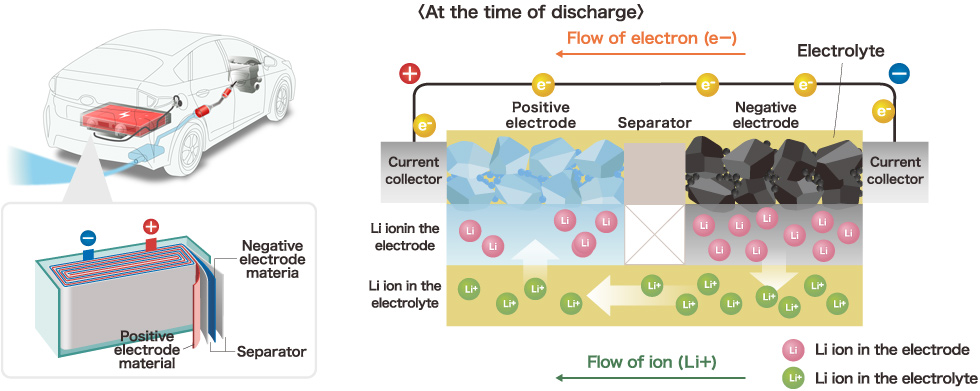

- Carbon Material for electric car battery (EV/PHV/HV)|Technology for the ...

![How Is An Electric Car Battery Made? [EV Battery Components]](https://i1.wp.com/axlewise.com/wp-content/uploads/2022/11/rechargeable-car-battery.jpeg)

The Basics of Electric Car Batteries

The Manufacturing Process

Innovations Driving Efficiency and Sustainability

The electric car battery manufacturing industry is constantly evolving, with new innovations and technologies being developed to improve efficiency and sustainability. Some of the key trends driving this shift include: Solid-state batteries: Solid-state batteries replace the liquid electrolyte with a solid material, which improves safety, energy density, and charging speeds. Recycling and repurposing: The development of closed-loop recycling systems and repurposing of battery materials is reducing waste and minimizing the environmental impact of battery production. Advanced materials: The use of advanced materials, such as graphene and nanomaterials, is improving the performance and efficiency of electric car batteries. The manufacturing process of electric car batteries is a complex and multi-stage process that requires careful attention to detail and a commitment to innovation and sustainability. As the demand for electric vehicles continues to grow, it's essential that the industry prioritizes efficiency, sustainability, and safety in the production of these critical components. By embracing new technologies and innovations, we can create a more sustainable and environmentally-friendly transportation system that benefits both people and the planet.Word count: 500